How Silk Carpets Are Made: From Cocoon to Craftsmanship

From Cocoon to Craftsmanship: Unveiling the Artistry of Silk Carpet Making.

The Process of Silk Production: From Silkworms to Cocoons

Silk carpets are known for their luxurious feel and exquisite beauty. They are a testament to the craftsmanship and skill that goes into their creation. But have you ever wondered how silk carpets are made? In this article, we will take you through the fascinating process of silk production, from silkworms to cocoons.

It all begins with the silkworms. These tiny creatures, also known as Bombyx mori, are the key to silk production. They are raised in controlled environments, where they are fed a diet of mulberry leaves. The silkworms have a voracious appetite and can eat several times their weight in leaves each day.

As the silkworms grow, they begin to spin their cocoons. This is where the magic happens. The silkworms produce a protein called fibroin, which is secreted through their salivary glands. As they spin their cocoons, the fibroin is extruded and solidifies upon contact with the air. The silkworms continue to spin until they have created a protective covering for themselves.

Once the cocoons are complete, they are carefully harvested. This is a delicate process, as any damage to the cocoons can affect the quality of the silk. The cocoons are gently boiled in water to soften the sericin, a natural gum that holds the cocoon together. This allows the silk fibers to be easily unraveled.

The next step is to unravel the silk fibers from the cocoons. This is done by carefully pulling the fibers from the softened cocoons. Each cocoon can yield a single strand of silk that can be up to 900 meters long. These strands are then twisted together to create a stronger, more durable thread.

Once the silk threads have been created, they are ready to be dyed. This is where the artistry comes into play. Skilled craftsmen carefully mix dyes to create the desired colors for the carpets. The silk threads are then immersed in the dye bath, where they absorb the color. The longer the threads are left in the dye bath, the deeper the color will be.

After the threads have been dyed, they are ready to be woven into carpets. This is a painstaking process that requires great skill and precision. The silk threads are carefully threaded onto a loom, and the weaver begins to create the intricate patterns and designs that are characteristic of silk carpets. Each knot is tied by hand, and the weaver must pay close attention to detail to ensure that the design is flawless.

Once the weaving is complete, the carpet is carefully washed to remove any excess dye or impurities. It is then stretched and dried in the sun. This helps to set the colors and gives the carpet its final shape.

The final step in the process is finishing. This involves trimming any loose threads and inspecting the carpet for any imperfections. Skilled craftsmen meticulously go over every inch of the carpet, ensuring that it meets the highest standards of quality.

And there you have it – the fascinating journey from silkworms to silk carpets. It is a process that requires patience, skill, and a deep appreciation for the art of craftsmanship. The next time you admire a silk carpet, take a moment to marvel at the incredible journey it has taken, from cocoon to craftsmanship.

Unraveling the Silk Thread: Techniques for Extracting Silk

Silk carpets are known for their exquisite beauty and luxurious feel. They have been prized for centuries, and their creation involves a meticulous process that begins with the extraction of silk from cocoons. In this section, we will unravel the techniques used to extract silk and understand the craftsmanship involved in creating these stunning carpets.

The journey of a silk carpet starts with the silkworms. These tiny creatures spin cocoons made of silk thread, which they use to protect themselves during the pupal stage. To extract the silk, the cocoons are carefully collected and sorted. Skilled craftsmen then employ various techniques to unravel the silk thread without damaging it.

One of the most common techniques used is called reeling. In this method, the cocoons are boiled in hot water to soften the sericin, a natural gum that holds the silk fibers together. The softened cocoons are then carefully unwound, and the silk thread is reeled onto a wooden or metal spindle. This process requires great skill and precision to ensure that the silk thread remains intact and undamaged.

Another technique used is known as throwing. In this method, the cocoons are first sorted according to their quality and color. Then, the silk threads from several cocoons are twisted together to form a stronger and more durable thread. This process is repeated multiple times until the desired thickness and strength are achieved. Throwing is often used for creating thicker silk threads that are suitable for weaving carpets.

Once the silk thread is extracted, it undergoes a series of treatments to enhance its quality and appearance. It is washed to remove any impurities and then bleached to achieve a uniform color. The silk thread is then dyed using natural or synthetic dyes, depending on the desired color palette. This dyeing process requires expertise to ensure that the colors are vibrant and long-lasting.

After the silk thread is prepared, it is ready to be transformed into a beautiful carpet. Skilled craftsmen use traditional hand-weaving techniques to create intricate patterns and designs. They carefully interlace the silk threads on a loom, following a predetermined pattern. This process requires great patience and attention to detail, as even the slightest mistake can ruin the entire carpet.

Once the weaving is complete, the carpet undergoes a finishing process. It is carefully washed to remove any remaining impurities and then stretched to ensure that it retains its shape. The carpet is then dried and ironed to give it a smooth and polished appearance. Finally, the edges are bound to prevent fraying and to give the carpet a finished look.

The craftsmanship involved in creating silk carpets is truly remarkable. From the delicate extraction of silk thread to the intricate weaving and finishing, every step requires skill and dedication. The result is a masterpiece that showcases the beauty and elegance of silk.

In conclusion, the process of creating silk carpets involves unraveling the silk thread from cocoons and transforming it into a work of art. The techniques used for extracting silk, such as reeling and throwing, require precision and expertise. The craftsmanship involved in weaving and finishing the carpets is equally impressive. The end result is a luxurious and stunning silk carpet that is sure to be cherished for generations to come.

Dyeing and Coloring Techniques for Silk Carpets

Silk carpets are known for their exquisite beauty and luxurious feel. One of the key factors that contribute to their allure is the dyeing and coloring techniques used in their creation. In this section, we will explore the fascinating process of how silk carpets are dyed and colored, from the moment the silk is harvested to the final masterpiece.

The journey of a silk carpet begins with the harvesting of silk from silkworm cocoons. These cocoons are carefully unraveled to obtain the raw silk fibers. The silk fibers are then sorted and cleaned to remove any impurities. Once the silk is ready, it is time to infuse it with vibrant colors.

There are several methods used to dye silk, each with its own unique characteristics. One popular technique is called natural dyeing, which involves using natural substances such as plants, flowers, and insects to create the desired colors. This method has been used for centuries and is still favored by many artisans today.

To create natural dyes, various plant materials are collected and processed. These materials are then boiled in water to extract the pigments. The silk fibers are immersed in the dye bath, allowing them to absorb the colors. The longer the silk remains in the dye bath, the deeper and more intense the color becomes. This process requires great skill and precision to achieve the desired shades and hues.

Another method used in dyeing silk carpets is synthetic dyeing. Synthetic dyes offer a wider range of colors and are often more vibrant and long-lasting than natural dyes. These dyes are created through chemical processes, where specific molecules are synthesized to produce the desired colors.

The synthetic dyeing process begins by dissolving the dye in water or a solvent. The silk fibers are then immersed in the dye bath, allowing them to absorb the color. The dye molecules penetrate the silk fibers, creating a permanent bond. After dyeing, the silk is rinsed to remove any excess dye and then dried.

In addition to dyeing, silk carpets can also be colored using a technique called printing. Printing involves applying color to specific areas of the silk using various methods, such as block printing or screen printing. This technique allows for intricate designs and patterns to be created on the silk.

Once the silk fibers have been dyed or colored, they are ready to be transformed into a beautiful carpet. Skilled craftsmen carefully weave the silk fibers into intricate patterns and designs, using traditional techniques that have been passed down through generations. The weaving process requires great precision and attention to detail, as each knot and stitch contributes to the overall beauty and durability of the carpet.

After the weaving is complete, the silk carpet undergoes a finishing process to enhance its appearance and texture. This may involve trimming the pile to achieve a uniform height, or adding a protective coating to increase the carpet’s longevity.

In conclusion, the dyeing and coloring techniques used in the creation of silk carpets are a true testament to the craftsmanship and artistry involved in their production. Whether using natural or synthetic dyes, these techniques bring life and vibrancy to the silk fibers, resulting in carpets that are not only visually stunning but also a joy to touch and walk on. The next time you admire a silk carpet, take a moment to appreciate the intricate process that went into its creation, from cocoon to craftsmanship.

Weaving Silk Carpets: Traditional Methods and Modern Innovations

Silk carpets are known for their exquisite beauty and luxurious feel. They have been prized possessions for centuries, adorning the floors of palaces and mansions. But have you ever wondered how these stunning works of art are made? In this article, we will take you on a journey from cocoon to craftsmanship, exploring the traditional methods and modern innovations involved in weaving silk carpets.

The process of making silk carpets begins with the cultivation of silkworms. These tiny creatures spin cocoons made of silk thread, which are carefully harvested. The cocoons are then boiled to soften the silk fibers, making them easier to unravel. This delicate process requires skill and precision to ensure that the silk threads remain intact.

Once the silk threads have been extracted from the cocoons, they are carefully sorted and spun into yarn. This yarn is then dyed using natural or synthetic dyes, depending on the desired colors. Traditional methods often involve using natural dyes made from plants, roots, and insects, while modern innovations have introduced synthetic dyes that offer a wider range of vibrant hues.

With the dyed silk yarn ready, the weaving process can begin. Traditional silk carpets are woven on looms, using a technique known as hand-knotting. Skilled craftsmen meticulously tie each individual knot by hand, creating intricate patterns and designs. This labor-intensive process requires patience and expertise, as even a small carpet can take months or even years to complete.

Modern innovations have introduced mechanized looms that can speed up the weaving process. These looms use computerized technology to replicate the hand-knotting technique, allowing for faster production without compromising on quality. While some purists argue that the charm and authenticity of hand-knotted silk carpets cannot be replicated by machines, others appreciate the efficiency and affordability that modern innovations bring.

Regardless of the method used, the weaving process is a true art form. It requires a deep understanding of color, design, and symmetry to create a visually stunning carpet. Skilled craftsmen often draw inspiration from nature, history, and cultural traditions, incorporating intricate motifs and symbols into their designs. Each carpet tells a unique story, reflecting the creativity and craftsmanship of its maker.

Once the weaving is complete, the silk carpet undergoes a finishing process. This involves trimming any excess threads, washing the carpet to remove any impurities, and stretching it to ensure a smooth and even surface. The final step is to add a protective backing to the carpet, which not only enhances its durability but also provides insulation and soundproofing.

Silk carpets are not only beautiful but also durable and long-lasting. The natural properties of silk make it resistant to stains, moisture, and fading, ensuring that your carpet will retain its beauty for years to come. However, it is important to care for your silk carpet properly, avoiding direct sunlight and regular vacuuming to prevent dirt and dust from settling into the fibers.

In conclusion, the process of making silk carpets is a labor of love that combines traditional methods with modern innovations. From the cultivation of silkworms to the intricate hand-knotting or mechanized weaving, each step requires skill, patience, and creativity. The result is a stunning work of art that adds elegance and luxury to any space. So the next time you admire a silk carpet, take a moment to appreciate the craftsmanship and artistry that went into creating it.

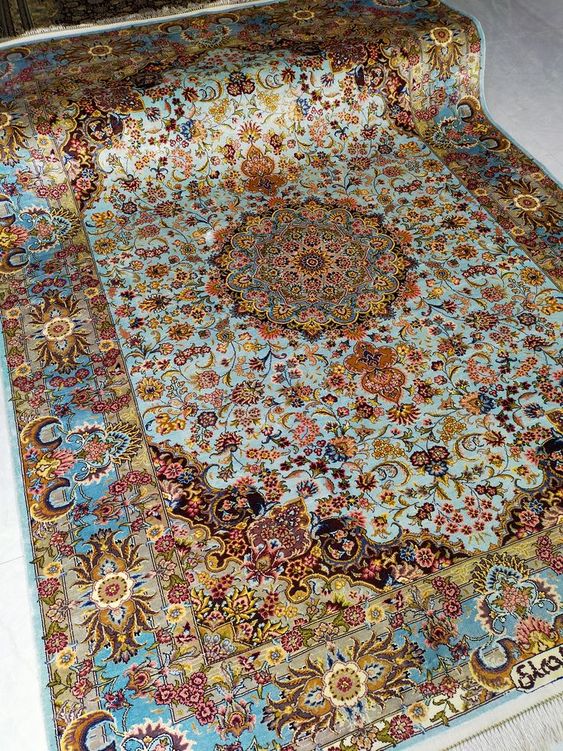

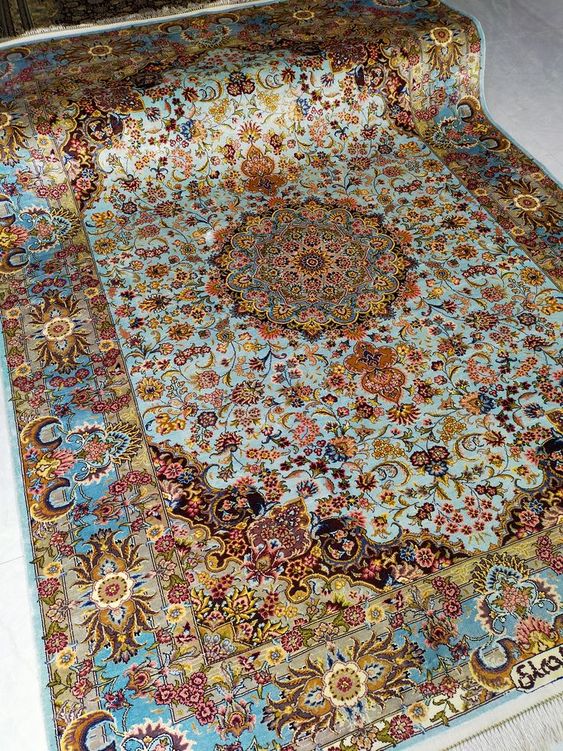

Embellishments and Patterns: Adding Intricate Designs to Silk Carpets

Silk carpets are known for their exquisite beauty and luxurious feel. They are a true testament to the craftsmanship and artistry of the people who create them. In this article, we will explore the process of adding intricate designs and embellishments to silk carpets, from the initial stages to the final product.

Once the silk threads have been extracted from the cocoons, they are carefully sorted and dyed. The dyed threads are then spun into yarn, which is used to create the base of the carpet. This base is known as the warp and weft, and it provides the foundation for the intricate designs that will be added later.

The next step in the process is to create the design for the carpet. This is often done by skilled artisans who have years of experience in creating intricate patterns. They use a variety of tools, such as graph paper and colored pencils, to sketch out the design. Once the design is finalized, it is transferred onto the warp and weft using a special technique called knotting.

Knotting is a time-consuming process that requires great skill and precision. The artisans carefully tie individual knots onto the warp and weft, following the design that has been transferred onto the fabric. Each knot is tied by hand, and the density of the knots determines the level of detail in the design. This is what gives silk carpets their unique and intricate appearance.

Once the knotting is complete, the carpet is ready for the next stage of embellishment. This can include a variety of techniques, such as embroidery, carving, or appliqué. These techniques add depth and texture to the design, making it even more visually appealing.

Embroidery is a popular technique used to enhance the beauty of silk carpets. Skilled artisans use a needle and thread to create intricate patterns and motifs on the surface of the carpet. This adds a three-dimensional quality to the design, making it stand out even more.

Carving is another technique that is often used to embellish silk carpets. This involves carefully cutting away sections of the fabric to create a raised pattern. The carved areas can then be further enhanced with paint or other decorative elements, adding depth and dimension to the design.

Appliqué is a technique that involves attaching small pieces of fabric or other materials to the surface of the carpet. This can be done to create a specific pattern or to add texture and visual interest to the design. The appliqué pieces are carefully sewn onto the carpet, creating a seamless and beautiful effect.

Once all the embellishments and patterns have been added, the carpet is carefully inspected for quality and durability. Any loose threads or imperfections are fixed, ensuring that the final product is of the highest standard.

In conclusion, the process of adding intricate designs and embellishments to silk carpets is a labor of love. Skilled artisans use a variety of techniques, such as knotting, embroidery, carving, and appliqué, to create stunning and visually appealing designs. The end result is a work of art that showcases the beauty and craftsmanship of silk carpets.

The Art of Finishing: Cleaning, Cutting, and Binding Silk Carpets

Silk carpets are not just beautiful works of art; they are also a testament to the skill and craftsmanship of the artisans who create them. From the moment the silk cocoon is harvested to the final touches of cleaning, cutting, and binding, every step in the process is carefully executed to ensure the creation of a stunning silk carpet.

Once the silk cocoons have been harvested, they are carefully unraveled to obtain the silk threads. These threads are then spun together to create a strong and durable yarn. This yarn is the foundation of the silk carpet and will determine its quality and longevity.

After the yarn has been spun, it is time to begin the weaving process. Skilled artisans use traditional looms to meticulously weave the silk threads into intricate patterns and designs. This is a time-consuming process that requires great attention to detail and precision. The weavers carefully follow the design, ensuring that each thread is in its proper place.

Once the weaving is complete, the silk carpet is ready for the finishing touches. The first step in this process is cleaning. The carpet is carefully washed to remove any dirt or debris that may have accumulated during the weaving process. This is done using gentle cleansers and techniques that will not damage the delicate silk fibers.

After the carpet has been cleaned, it is time to cut and trim the edges. This is done to give the carpet a neat and finished appearance. Skilled craftsmen use sharp scissors to carefully trim the edges, ensuring that they are straight and even. This step requires a steady hand and a keen eye for detail.

Once the edges have been trimmed, it is time to bind the carpet. Binding is the process of securing the edges of the carpet to prevent fraying and unraveling. This is done using a strong and durable thread that matches the color of the carpet. The binding is carefully sewn along the edges, creating a neat and finished look.

The final step in the finishing process is stretching and blocking the carpet. This is done to ensure that the carpet is perfectly flat and free from any wrinkles or creases. The carpet is stretched and secured to a frame, allowing it to dry in its desired shape. This step is crucial to ensure that the carpet maintains its shape and appearance over time.

Once the carpet has been stretched and blocked, it is ready for inspection. Skilled craftsmen carefully examine the carpet, checking for any imperfections or flaws. Any necessary repairs or adjustments are made at this stage to ensure that the carpet meets the highest standards of quality.

In conclusion, the art of finishing a silk carpet is a meticulous and intricate process. From cleaning and cutting to binding and stretching, every step is executed with precision and care. The result is a stunning silk carpet that is not only a beautiful work of art but also a testament to the skill and craftsmanship of the artisans who create it. So, the next time you admire a silk carpet, take a moment to appreciate the artistry and dedication that went into its creation.